A piece of research equipment made by students will be used in the Edward E. Whitacre Jr. College of Engineering.

What started as a capstone project handed to a group of students in Texas Tech University’s Edward E. Whitacre Jr. College of Engineering has yielded a useful tool for future research.

Given the opportunity to select a project, the undergraduate students in the Department of Mechanical Engineering leaned into helping current and future graduate students by creating a tool that could be used in rocket research.

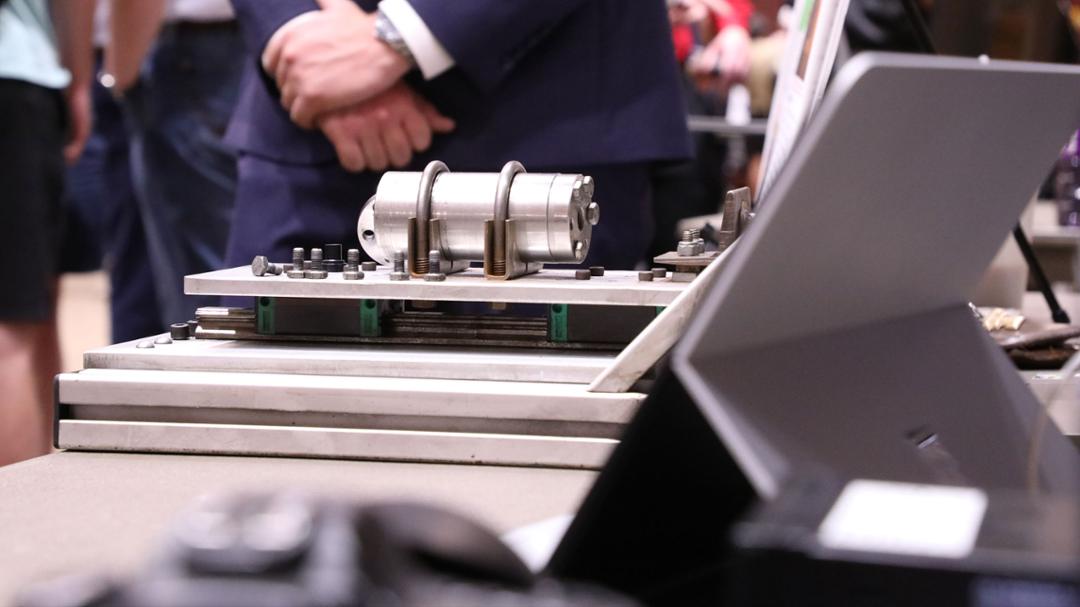

The equipment built by the students is called a thrust stand, and if you’re not exactly sure what that is, you’re not alone.

“Basically, a thrust stand is a mounted rocket motor,” explained Joseph Pantoya, one of the mechanical engineering students involved in the project. “It collects thrust and pressure data for a given rocket fuel.

“What we can do is get fuels that the combustion lab makes, put them in our rocket motor and test them out in a controlled environment.”

The capstone course brought together a team of six students from diverse backgrounds to complete the final steps in their mechanical engineering degrees with their project supported by grants from the U.S. Department of Energy (DOE) and the U.S. Department of Defense (DOD).

Grants from sources like DOE and DOD give professors the resources needed to supply students with a hands-on learning experience while also creating something of value for the wider world.

In this case, the thrust stand will be used by both graduate and undergraduate students in the Combustion Lab, where testing of accelerants used in various types of rockets takes place daily. The capstone project will help researchers test solid fuel combustion and better understand how those fuels can be designed to advance hypersonic combustion for propulsion applications.

“Being able to help students in the lab publish research papers one day with something we designed is really cool,” said Juan Aguirre, another of the students involved with the thrust stand project.

The project required working with graduate students in the lab to understand and address their needs in the design phase. Meeting the needs of those students was a critical piece of the puzzle, but it wasn’t the only piece.

Moving from the theoretical aspects of design into the actual production phase, managing a budget and producing a useful final product were all hurdles the thrust stand team had to conquer.

“We had a lot of challenges,” team member Ajibek Karatalov said. “Most of the challenges were logistical. For example, one of the main parts was shipped from Japan, and it never made it. I don't know why. So, these kinds of challenges were sort of boundaries, but I'm glad that we overcame them as a team.”

Luckily for the students, there are plenty of resources and mentors to lean on. Mechanical engineering’s machine shop, for instance, provided the expertise the students needed to work through many of the technical issues along with the sage advice that comes from working with professionals.

“I think having the shop instructors, Roy Mullins and David Meyers, they kind of gave us a new perspective on the issues we were facing,” said Jeffery (Mitch) McHugh, another team member. “They had more of a rounded perspective because they’ve worked in the field. That really helped us and gave us a perspective of what people that we may be working with in the future will have to say.”

The team’s design was on display at the Mechanical Engineering Expo, an event held on Texas Tech’s campus where, along with other teams from the department, the work of the last year is shown off to the campus community.

Mullins and the staff at the machine shop work with a wide range of students daily, helping with things like welding and machining parts that wouldn’t normally be done by engineers in the field, and he was impressed with the thrust stand team’s competency.

“They’ve been a pretty self-sufficient group, actually,” Mullins said. “We’ve had to answer the usual technical questions and assist them in some machining, but for the most part, with the end design they’ve done really well on their own.

“It was a very specific subject. It was a research project tied to research we do in the department, so that was kind of unique in and of itself. But what really struck us about this project was it was for a research project that ties immediately to a critical problem.”