John Granier and his team at Element U.S. Space & Defense will join the Texas Tech Combustion Lab to research combustion dynamics in gun chambers.

Click.

When the trigger of a gun is pulled and this sound follows rather than the expected bang, it can lead to the same disappointment from a lit firework deemed a dud. Curiosity often follows, as to what could have possibly gone wrong?

The seconds that follow can turn deadly.

During this instance, known as a hang fire, the hammer or firing pin of the gun fell and although the shot was not immediate, the ignition process was initiated. This means a delayed discharge is imminent, unbeknownst to the operator.

In the case of this man target practicing in a wooded area, when he couldn’t figure out why his gun didn’t shoot, he placed it on a folding table in front of his chair and stood. Before he could take a step, the gun fired – hitting a water jug in front of him with an explosion of water. The pure shock knocked him to the ground, head reeling as he tried to figure out what had just happened.

There is a much closer call caught on camera, but viewer discretion is advised. This man decided to look down the barrel of his rifle after it failed to shoot. The recoil from the hang fire inched the bullet to the rim of his cap, leaving a chilling hole he later shows the camera.

While hang fires aren’t considered an often occurrence, they’re a problem the U.S. Department of Defense (DOD) doesn’t take lightly. That’s why the DOD has made a multimillion-dollar investment to explore the intricate process of gun propellant ignition and its effects on interior ballistics through a workforce development program led by Michelle Pantoya, the J.W. Wright Regents Endowed Chair Professor in the Department of Mechanical Engineering at Texas Tech University.

“Addressing issues like hang fires, pressure spikes or incomplete burns is the underlying motivation for all of this,” Pantoya said. “Repeatability and reliability are factors that need to be improved. We could optimize systems to reduce the risks associated with misfires or unintentional behavior.”

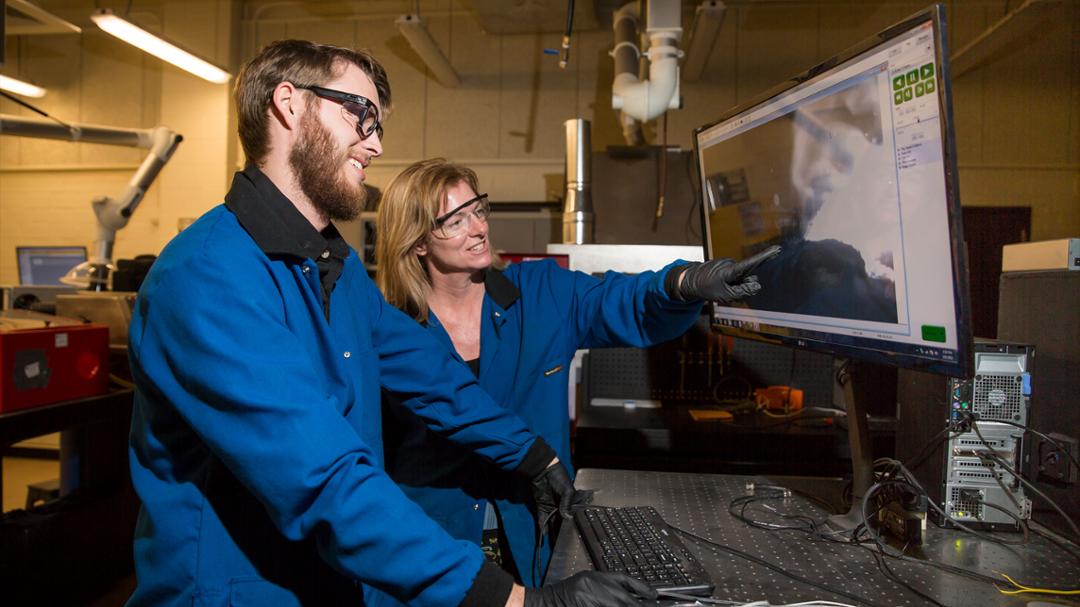

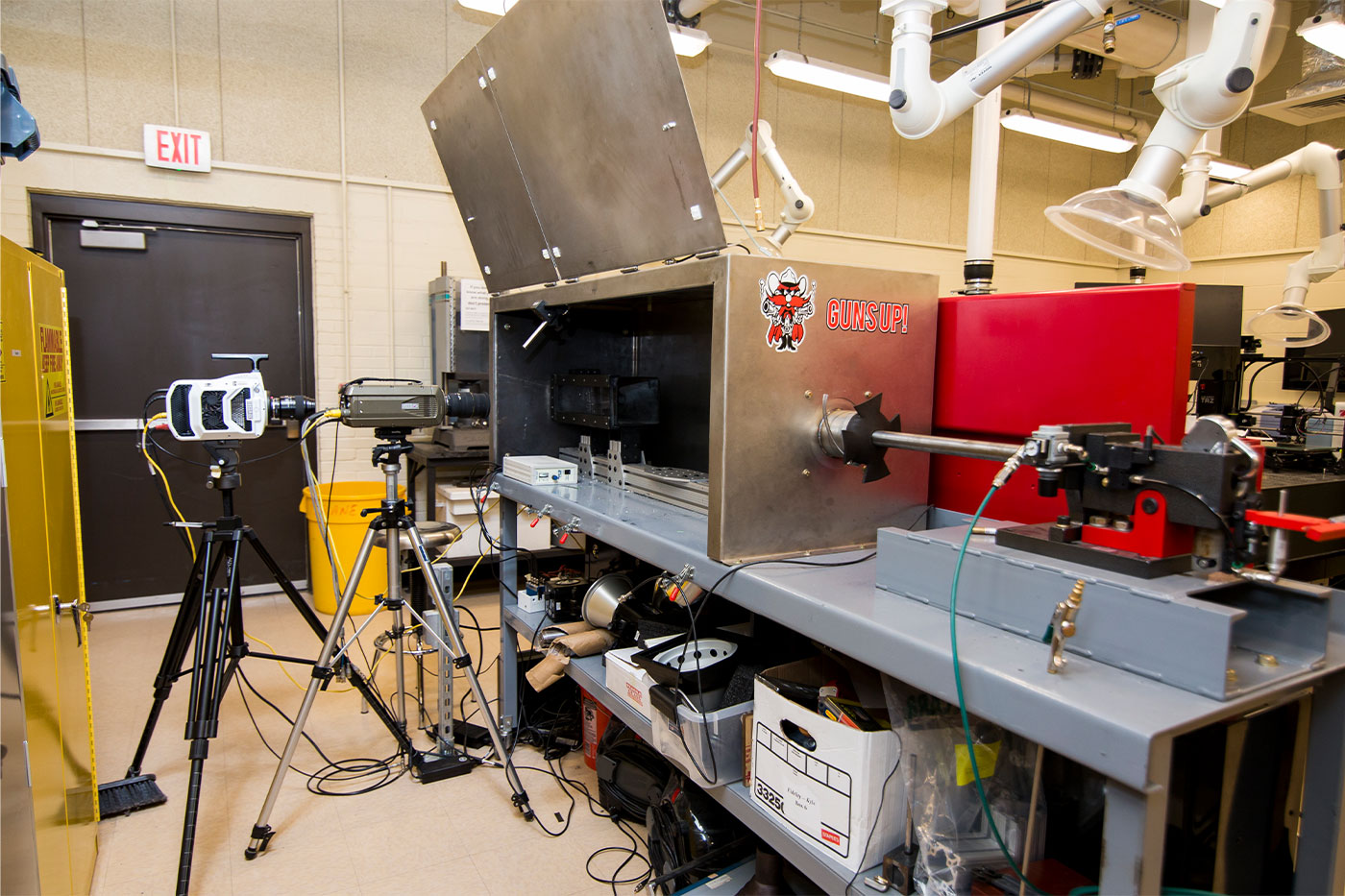

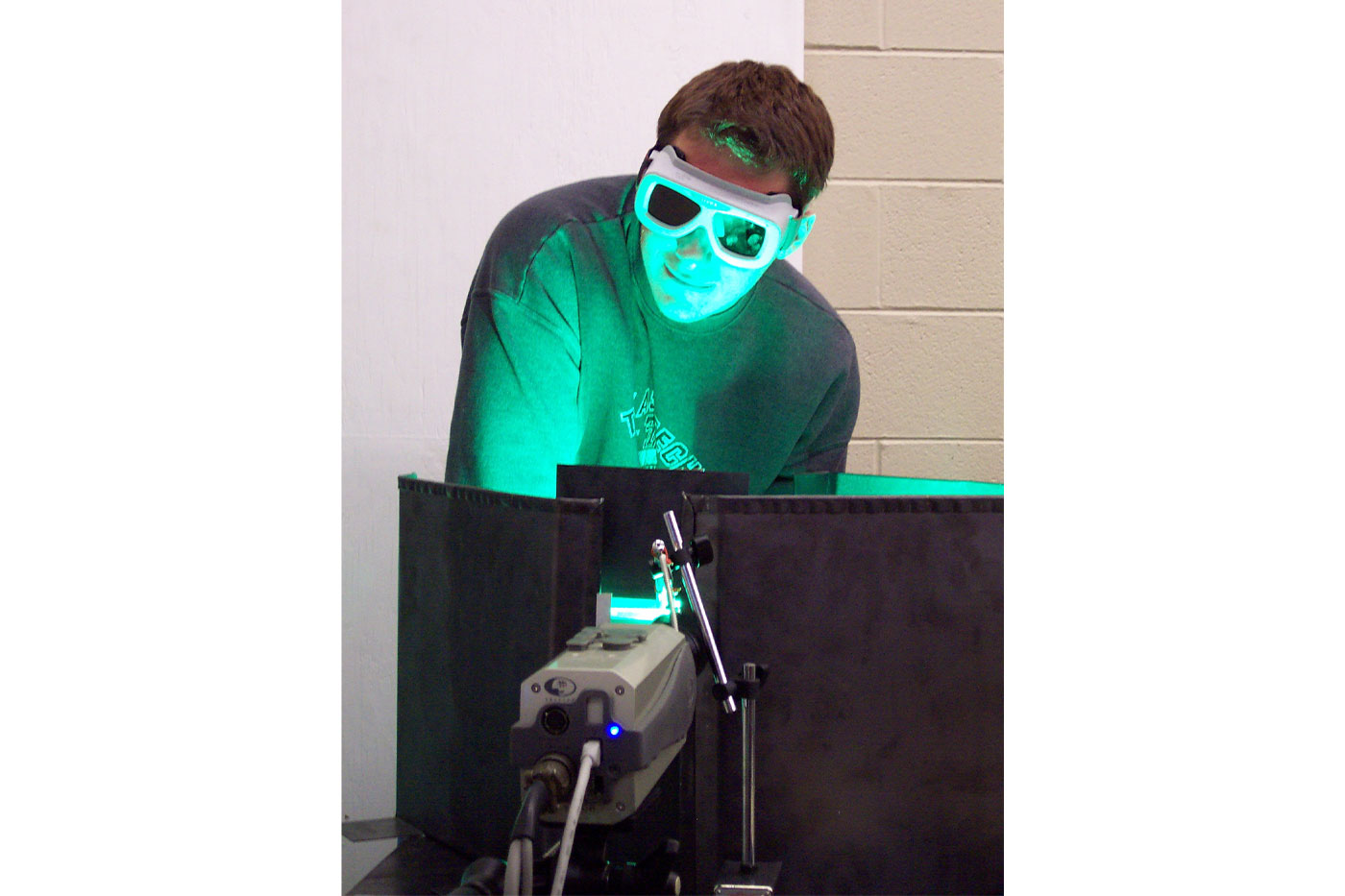

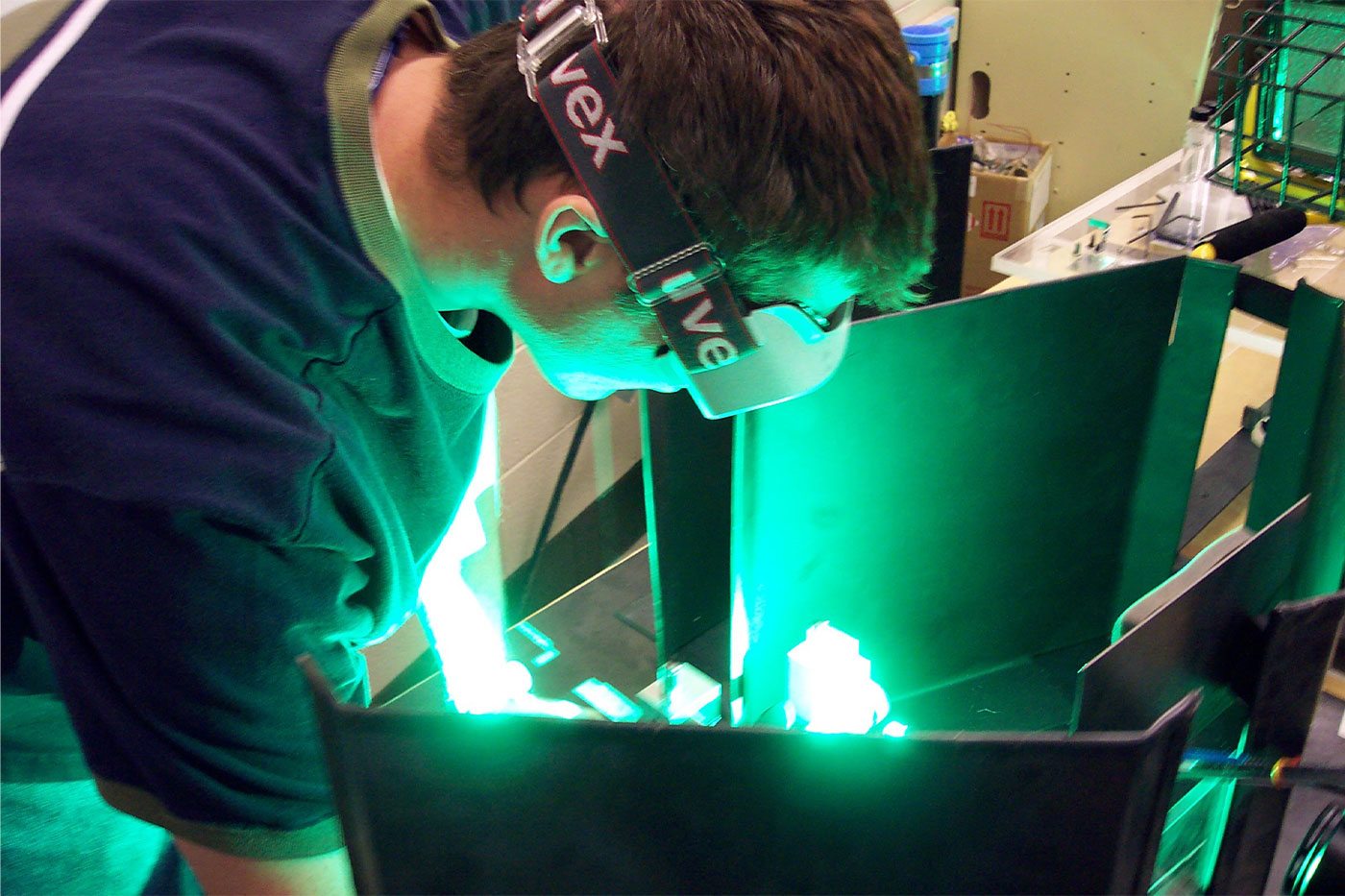

Through her Combustion Lab and its diagnostic system developed in-house, Pantoya will help the DOD predict and model gun chamber ignition. Her high-speed cameras are paired with the ability to capture emissions in discrete wavelengths – one of very few existing applications for high-speed digital imaging thermography.

This system – and expertise in contributing to fundamental science – will allow Pantoya and her team to explore the physics behind the fluid flow, heat transfer and combustion processes of propellant ignition. That knowledge can provide the answers needed to make firearms more affordable, reliable and safe (especially for military use).

“For us to be able to study these multiphase reactions at Texas Tech is going to be transformative,” Pantoya acknowledged. “It could launch us into cutting-edge research that will address issues in hypersonic propulsion, for example, because that’s another emerging application of solid propellants. Our research could really impact energy generation technologies in our future.”

Pantoya anticipates four of the 20 undergraduates to doctoral students in the Combustion Lab will be able join this project and work with the U.S. Army Combat Capabilities Development Command Armaments Center at Picatinny Arsenal in Morris County, New Jersey.

But she is looking forward to another collaboration in particular – an industry partnership that reunites her with John Granier, her former graduate student.

“It’s always fun to work with alumni,” she noted. “I get to continue working with someone who I really enjoyed watching reach a high level of professional development that propelled them far beyond Texas Tech.”

Granier is the chief engineer of munitions and energetics at Element U.S. Space & Defense, which has been a longstanding government testing partner and innovator in space exploration since the 1960s. But he knew he had “the knack” for engineering long before he coordinated a team of scientists and subject matter experts to work alongside his alma mater.

Curious about Combustion

Granier admits his initial draw to Texas Tech in 1997 was the long distance from his hometown near Houston. He was eager to start a new chapter, one where he could delve into the talents his friends and family had already recognized in him – taking things apart and fixing them.

“As far as being curious of how things work and solving problems myself, I was always into that,” he remembered.

Equipped with an honors scholarship, Granier enrolled in what is now the Edward E. Whitacre Jr. College of Engineering and majored in mechanical engineering. He wasted no time getting involved in many activities and societies on campus.

While Granier jokes he was initially naïve about what engineers did, he gained more experience by taking internships every summer that also helped fund his tuition.

“They were very diverse, and none of them were related to what I’m doing now,” he admitted, “but I still apply things that I learned all the time.”

By the time Granier graduated in 2001, he decided he couldn’t quite leave Lubbock. Not when he had the chance to become Pantoya’s first graduate student, during which he helped create the Combustion Lab by establishing facilities and purchasing and installing equipment.

Even more impactful were the skillsets Granier began to develop by designing experiments mainly focused on characterizing ignition and combustion behaviors of nanothermites, a family of highly reactive materials.

“Dr. Pantoya gave me a lot of freedom and responsibility for the Combustion Lab,” he said. “I had a lot of ownership in accomplishing research goals, and then teaching other research students. That was very influential in my career.”

Granier earned his Master of Science in Mechanical Engineering in 2003, but still believed his time on campus was integral enough to pursue his doctoral degree. He became the lead instructor of a third-year heat transfer course and completed calorimetry and activation energy studies of nanothermites.

This time, graduating in 2005 with a doctorate in mechanical engineering, Granier left Texas Tech ready to transition from helping the DOD in the Combustion Lab to assisting them full-time.

“I wasn’t in the military myself, but I figured I could help the military by designing cool engineering toys for them,” he mused. “Basically, I’ve led projects that developed prototypes and tools and I’ve seen soldiers use those tools effectively. All of my engineering has been in a field I love, related to explosives, ballistics and pyrotechnics. So, I would do this job for free, but I’m happy I get paid to do it.”

It did not take long for Granier to discover his education at Texas Tech was crucial to his career. When he joined a small startup business in 2007, called Energetic Materials and Products Inc. (EMPI), he began to duplicate the Combustion Lab practices on a larger scale.

As he created and launched products that integrated chemical, electrical and mechanical design elements, Granier kept in contact with Pantoya not just to collaborate on projects, but to hire the best talent per her suggestions.

“I think I hired maybe 10 to 15 undergraduates to graduate students from Texas Tech during that 17-year timeline,” he remembered. “I understood what position those students were in, and then they were giving me feedback about what was going on at the Combustion Lab, so I could give them a more hands-on, wider perspective.”

Granier considers himself a mentor to these students, as he can remember how influential his internships and work experience were before entering the workforce. Mechanical engineering is a broad industry, and his advice for students is to keep their mind open to many different opportunities and connect the dots until they’re led to a spectacular role.

“It’s not about what the company can get out of the kid,” he stated. “It’s about growing young engineers.”

Full Circle Impact

Granier joined Element U.S. Space & Defense at the beginning of this year – a dream job he never knew existed as a student. Pantoya, aware of his position, thought a partnership with his new company would be key to develop a well-rounded task force instrumental to the U.S. Defense sector.

After discovering the connection between sponsors and project goals, Granier also felt like this project was a perfect fit for Element U.S. Space & Defense. He worked with his former professor to establish details and a division of labor that would work from both perspectives. Pantoya is pleased the collaboration will enable her team to kickstart the program sooner than normal.

They decided the initial study will primarily take place at the Combustion Lab, with Element U.S. Space & Defense’s ballistics experts supporting in experiment design and data analysis. It is expected this effort will grow to larger experiments of full-scale guns and artillery with Element U.S. Space & Defense’s Camden facility playing a significant role.

Located in Arkansas, the Camden facility is a comprehensive ordnance and ballistic test center, renowned for its state-of-the-art lab and testing capabilities. The laboratory is equipped to conduct a myriad of tests on weapon systems, ordnance, rocket motors and hazardous materials, supporting a wide range of military systems, including live firings, environmental, dynamics and explosive testing.

“The expertise of Element U.S. Space & Defense’s engineers and the extensive capabilities of their Camden facility will be crucial in enhancing our experimental design, analysis and overall results,” Pantoya said. “We anticipate that this research will not only advance the DOD’s work but also provide valuable insights for weapon designers and develop new diagnostics applicable across various fields.

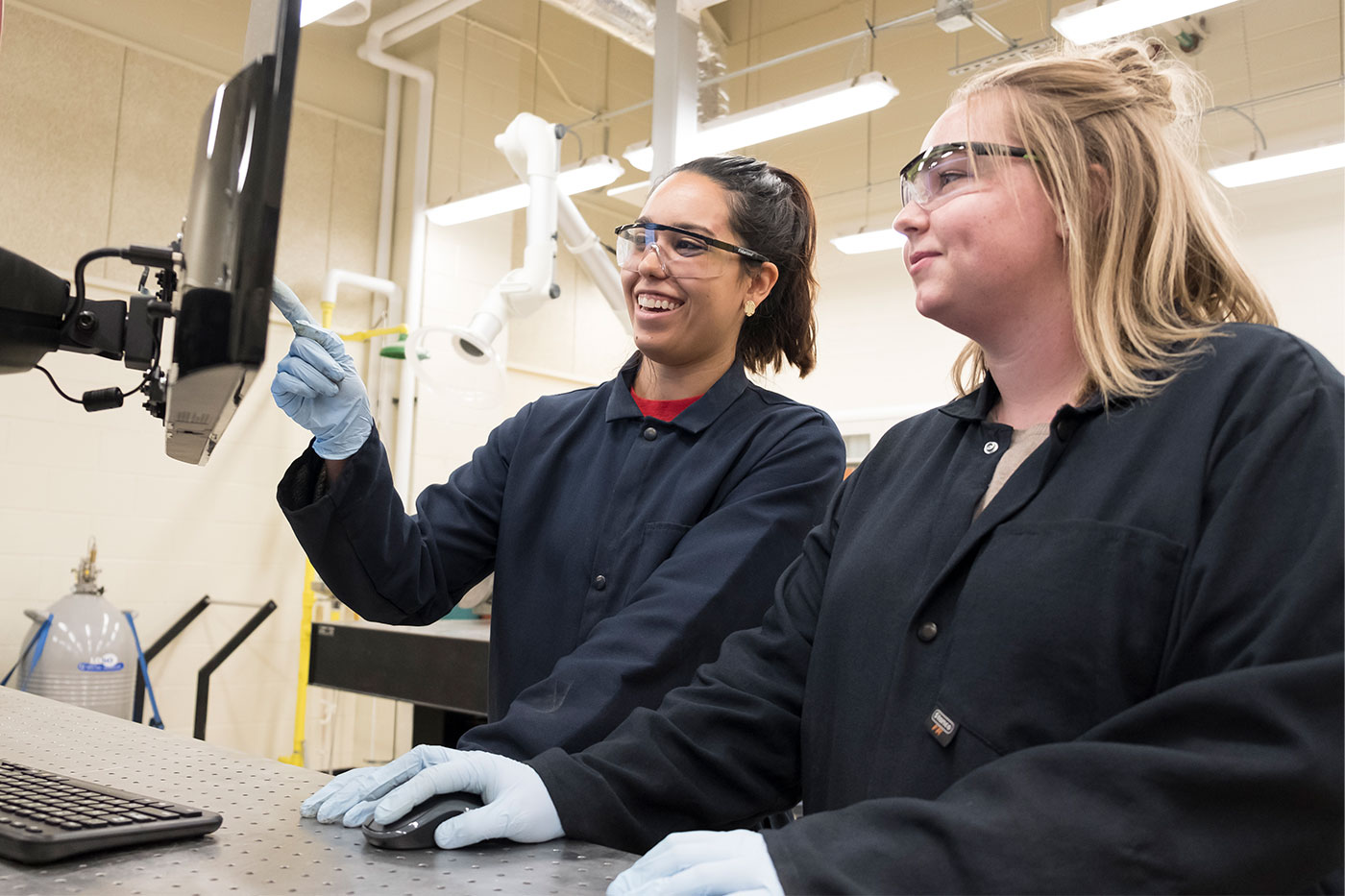

“Additionally, this project offers a significant opportunity for our graduate-level engineering students to gain hands-on experience and contribute to innovative research.”

After spending 24 years as a faculty member at Texas Tech, Pantoya knows the most effective way to train students is to pair them with external peers like Army scientists struggling with real-life challenges. Students become more vested in the problem solving and dive into the science and engineering at a higher level. This further increases their learning and consequently, their contributions.

“Then, to have a subject-matter expert from industry giving students perspective on not just the learning component of the project but how that learning extends to product development, that is a phenomenal addition to a project from a student’s perspective,” she said. “So, it’s fun, because we have clear vested interest from our DOD collaborators and generous support of time commitments from industry that is making the students’ experiences so much more well-rounded.”

Whether these students spend a week onsite with Granier or work with him for a summer, he believes their time spent together will be mutually beneficial as they attempt to tackle problems that are nearly a century old.

He also is fully on board with Pantoya’s main objective to enhance student development – a top priority for him personally and professionally.

“We hope that we can cultivate both students and a novel thermographic diagnostic technique,” he noted. “Then, both of those can be brought into our company later.”

These kinds of student experiences will last a lifetime, and Pantoya only has to look to Granier as a reminder of the impact her Combustion Lab has made on the future of mechanical engineering.

“I’m grateful to have former students who have become very successful in their careers take the time to reach out to Texas Tech and see if there’s any mechanism for us to continue collaborating on some level,” Pantoya said. “I think our former students are doing amazing things everywhere, and being able to work together is a blessing.”